G.E.L.

Johnson & Johnson challenged the team with finding the future of wound care. The boundaries were fairly open, so we were free to explore different avenues. We focused on bandages and what opportunities could be found there.

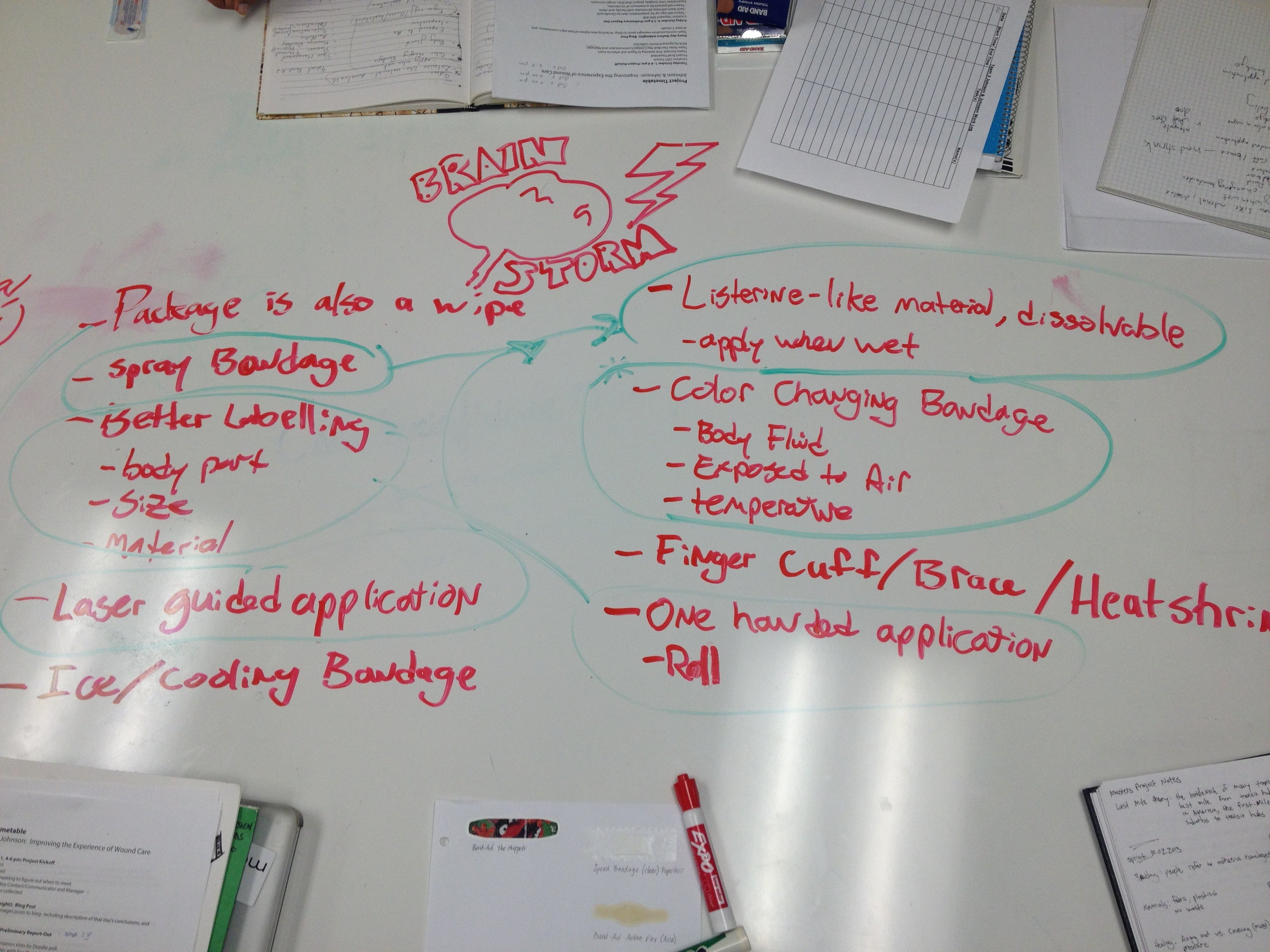

Brainstorming

The group, made up of designers, engineers and business developers, started by brainstorming areas of opportunities and various pain points in the bandage process.

The group, made up of designers, engineers and business developers, started by brainstorming areas of opportunities and various pain points in the bandage process.

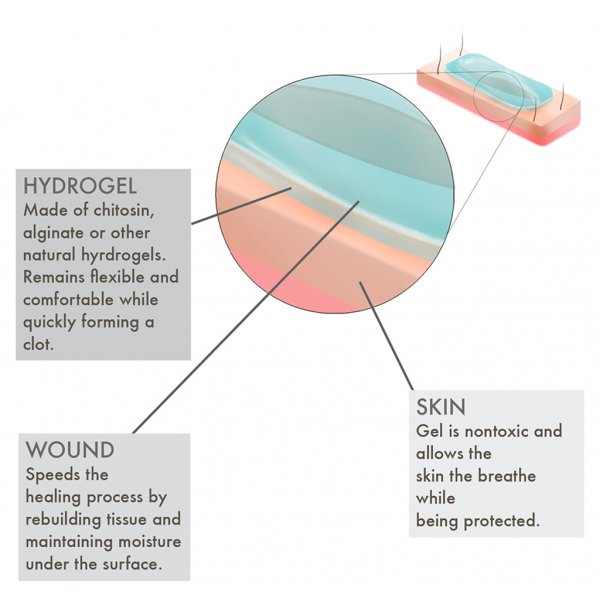

The team came up with a solution involving hydrogel. Hydrogel is made of chitosan and is being researched by the military for on the field wound sealing.

The team came up with a solution involving hydrogel. Hydrogel is made of chitosan and is being researched by the military for on the field wound sealing.

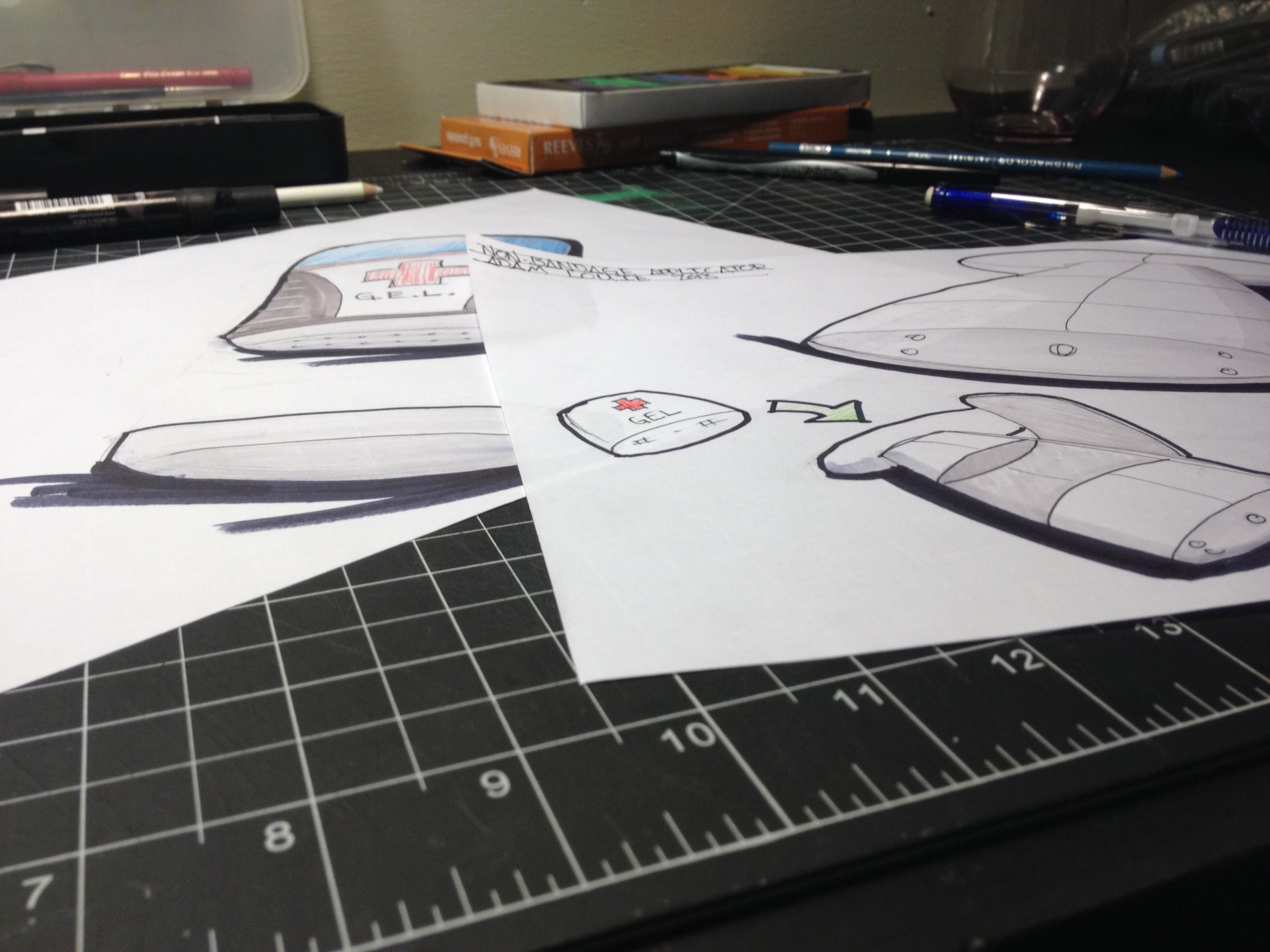

Sketches

We needed a way to dispense the gel. Various sketches were made in how best to store and deliver the product.

Prototyping

To take the concept further, the team attempted to create a few prototypes to test the feasibility of the delivery.

Pink foam mockups were tested for form and feel.

A packet filled with hand soap was created to test how the action of applying the gel would feel to users.

A packet filled with hand soap was created to test how the action of applying the gel would feel to users.

A basic form made from Sculpey and a syringe filled with hand sanitzer was used to test the application of the product.

A basic form made from Sculpey and a syringe filled with hand sanitzer was used to test the application of the product.

A more refined version of the Sculpey model was made, which faired a little better. A supository bulb was used to hold the product. This design informed us that the applicator needed channels to control the delivery in a uniform manor.

A more refined version of the Sculpey model was made, which faired a little better. A supository bulb was used to hold the product. This design informed us that the applicator needed channels to control the delivery in a uniform manor.

The final concept.

The final concept.

A photoshop recreation of the process.

A photoshop recreation of the process.